2003v E500 W211 SRS Braking System Making Constant Electrical Noise: Understanding and Resolving the Issue

If you own a 2003v e500 w211 srs braking system making constant electrical noise, you may have encountered a peculiar and persistent electrical noise emanating from the SRS (Supplemental Restraint System) braking system. This issue, while relatively common, can be both frustrating and concerning. At Sphere Magazines, we aim to equip you with the insights you need to understand this problem, its potential causes, and the steps you can take to address it effectively. Whether you’re a seasoned car enthusiast or someone aiming to maintain their W211’s reliability, this detailed guide will help.

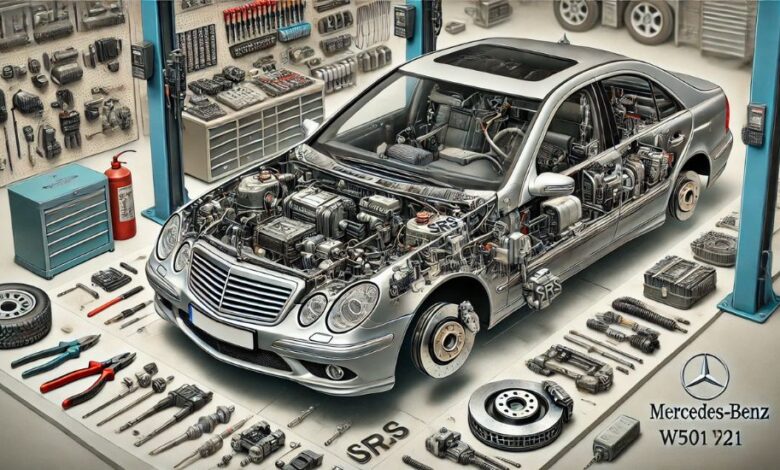

What Is the 2003v E500 W211 SRS Braking System?

The 2003 Mercedes-Benz E500 (W211) was one of the most advanced luxury sedans of its time, boasting a sophisticated braking system that integrated modern safety technologies. The SRS braking system in this model is a part of the vehicle’s broader safety suite. This system works in conjunction with airbags and other electronic controls to enhance driver and passenger protection during emergencies. Specifically, the SRS braking system includes features like:

- Brake Assist (BAS): Provides additional braking force during emergencies.

- Electronic Stability Program (ESP): Maintains vehicle stability by controlling wheel slip.

- Sensotronic Brake Control (SBC): An advanced electro-hydraulic braking system that optimizes brake distribution.

However, while these features elevate safety and performance, they also come with intricate electronic components prone to wear and failure, leading to issues like the constant electrical noise that many owners report.

Causes of Constant Electrical Noise in the SRS Braking System

A persistent electrical noise from the SRS braking system can stem from various underlying factors. Identifying the root cause is crucial for resolving the issue effectively. Below are some common culprits:

1. Faulty SBC Pump Motor

The Sensotronic Brake Control (SBC) system relies on a pump motor to generate hydraulic pressure for the brakes. Over time, this motor can develop wear, resulting in a continuous buzzing or whining sound. The noise may persist even when the vehicle is stationary, as the pump struggles to maintain adequate pressure.

2. Sensor Malfunctions

The SRS braking system uses multiple sensors to monitor wheel speed, braking force, and other parameters. A malfunctioning sensor can send incorrect signals to the control unit, causing abnormal behavior and audible electrical noise.

3. Low Hydraulic Fluid Levels

The SBC system depends on hydraulic fluid for proper operation. If the fluid level drops below the recommended threshold due to leaks or improper maintenance, the pump may overwork, leading to a constant electrical noise.

4. Aging Electrical Components

As the vehicle ages, electrical components such as relays, wiring, and control modules may degrade. Corrosion, loose connections, or short circuits can result in continuous noise from the SRS braking system.

Signs That Require Immediate Attention

While the noise itself is a clear indication of an issue, other symptoms often accompany this problem, signaling the need for prompt action:

- Frequent Warning Lights: The SBC or brake warning light may illuminate on the dashboard.

- Reduced Brake Performance: You might notice increased stopping distances or a spongy brake pedal.

- Intermittent Brake Failure: In severe cases, the brakes may fail to engage temporarily.

- Burning Smell: Overheating components can emit a noticeable odor.

If you observe any of these symptoms alongside the electrical noise, it’s essential to address the issue immediately to avoid compromising your safety.

Diagnosing the Problem

Proper diagnosis is key to resolving the electrical noise in the SRS braking system. Here are some steps you can take or request from a professional mechanic:

1. Inspect the SBC Pump Motor

A thorough inspection of the SBC pump motor can reveal wear or damage. Listen for unusual sounds when the brakes are applied and check for overheating components.

2. Check Hydraulic Fluid Levels

Ensure that the hydraulic fluid is at the recommended level. If fluid levels are low, inspect the system for leaks and refill using the correct type of fluid specified in your owner’s manual.

3. Scan for Error Codes

Using a diagnostic tool, scan the vehicle’s ECU (Engine Control Unit) for error codes related to the SRS braking system. These codes can provide valuable clues about the underlying issue.

4. Test Electrical Connections

Examine the wiring and connectors associated with the SRS braking system. Look for signs of corrosion, frayed wires, or loose connections that may contribute to the noise.

Resolving the Issue

Once the problem has been diagnosed, the appropriate repair or maintenance steps can be taken. Below are some potential solutions:

1. Replace the SBC Pump Motor

If the pump motor is the source of the noise, replacing it is often the best course of action. While this can be a costly repair, it’s essential for restoring the braking system’s functionality and eliminating the noise.

2. Repair or Replace Sensors

Malfunctioning sensors should be repaired or replaced as needed. This may involve recalibrating the system to ensure accurate operation.

3. Refill Hydraulic Fluid

If low fluid levels are causing the noise, refill the system using the recommended fluid type. Address any leaks to prevent the problem from recurring.

4. Upgrade Electrical Components

Replace aging or damaged electrical components, such as relays or wiring. This step can improve overall system performance and eliminate unwanted noise.

Preventive Maintenance Tips

To avoid encountering similar issues in the future, it’s essential to prioritize regular maintenance. Here are some tips:

- Schedule Routine Inspections: Have your braking system inspected by a qualified mechanic at regular intervals.

- Monitor Fluid Levels: Check hydraulic fluid levels frequently and top off as needed.

- Address Warning Signs Promptly: Don’t ignore dashboard warning lights or unusual sounds.

- Use Quality Parts: When replacing components, opt for high-quality, OEM (Original Equipment Manufacturer) parts.

Why Addressing the Issue Matters

Ignoring the constant electrical noise from your 2003v E500 W211 SRS braking system can have serious consequences. Beyond the annoyance, unresolved issues can lead to:

- Compromised Safety: Reduced braking performance increases the risk of accidents.

- Costly Repairs: Delaying repairs may result in more extensive damage and higher repair costs.

- Reduced Vehicle Value: Persistent mechanical issues can lower your car’s resale value.

By addressing the problem promptly, you can ensure a safer and more enjoyable driving experience while preserving the integrity of your Mercedes-Benz E500.

Final Thoughts

The 2003v E500 W211 SRS braking system making constant electrical noise is a common issue that requires immediate attention. Understanding the potential causes, diagnosing the problem, and implementing the right solutions are crucial steps in maintaining your vehicle’s performance and safety. At Sphere Magazines, we believe in empowering car owners with knowledge to keep their vehicles in optimal condition. By staying proactive and prioritizing regular maintenance, you can enjoy the luxury and reliability that your Mercedes-Benz E500 was designed to deliver.